9 Common Issues With Radiant Floor Heating — And Some Solutions

We may receive a commission on purchases made from links.

A radiant floor heating system has many advantages, but as with any mechanical home system, it occasionally requires repair as components wear out. The best way for homeowners to keep their floor heat in good working condition is to make sure they understand the basic parts and operation of their radiant floor heating system. Troubleshooting likely problems (and possibly performing your own repairs) won't be possible unless you understand exactly how your system works, where all the components are located and what problems are likely to occur.

Radiant Floor Heating System Parts

Radiant Floor Heating System Parts

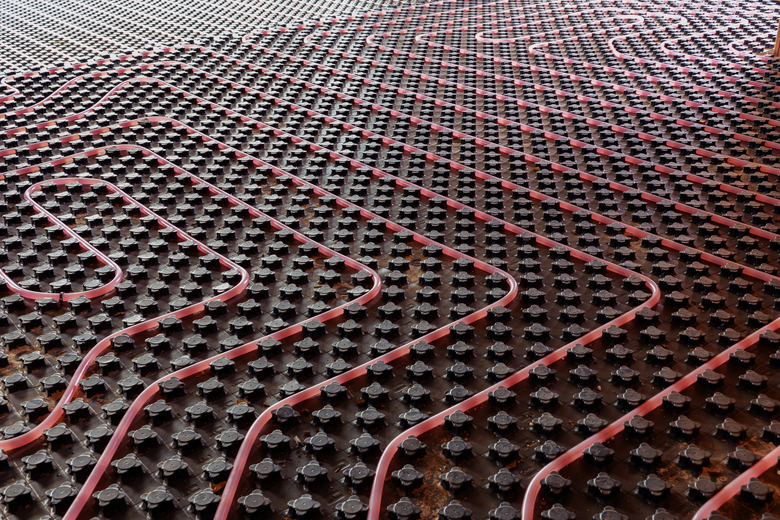

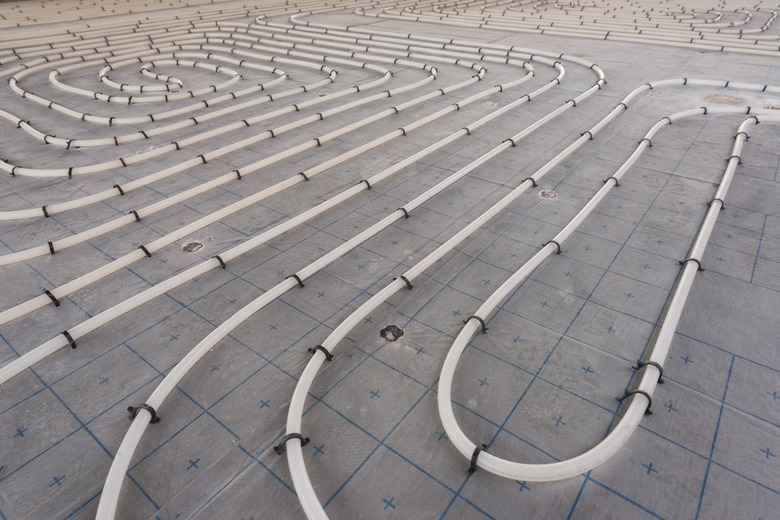

Radiant floor heating systems work by circulating hot water through polyethylene (PEX) tubing installed within, above or below the subfloor. These systems are relatively simple systems in principle, but they have several mechanical components that can be the source of problems:

- A boiler (or water heater) heats the water for circulation through the tubing. In most systems, the boiler serves only the radiant floor system, but some systems also use the boiler for domestic hot water used throughout the house.

- The circulating pump moves water from the water heater through the tubing and back to the water heater. In some designs, there is a separate circulating pump for each heating zone, while in other systems, a single pump pushes water through the entire system.

- The manifold is a brass and copper array that divides the main hot water line coming from the water heater into individual loops (zones) to heat various rooms. The manifold sometimes integrates the zone valves.

- Zone valves control the flow of water through different branches of the tubing. There is usually one zone valve to serve each heating loop. Zone valves are usually powered by low-voltage, 24-volt current supplied by a transformer that steps down 120-volt household current.

- Thermostats monitor room temperature and open and close the zone valves as needed to govern the amount of hot water flowing under the floor. There may be a single thermostat that includes connections for all zone valves, or each room can have its own thermostat controlling an individual zone.

1. The boiler needs replacing.

1. The boiler needs replacing.

The boiler or water heater that serves a hydronic radiant floor heating system has many of the same features as any consumer water heater or boiler: an expansion chamber, pressure gauge, and pressure-relief valve. There may also be an air bleed valve as part of the plumbing connection array, which allows air to be removed from the system when necessary.

Problems with the boiler or water heater are rare, but any of these major components can develop problems that require attention from a plumber or HVAC specialist. There is a typical life expectancy for any water heater or boiler. With a flooring system served by a dedicated water heater, eight to 12 years is considered a typical life span. If your radiant floor heating system is served by a boiler, 15 to 20 years is an average life expectancy. In most cases, replacing this major component will be a job for a plumbing or HVAC specialist.

2. The floors don't warm up like they should.

2. The floors don't warm up like they should.

When the circulating pump on a radiant floor heating system develops problems, you may notice that the floors do not warm up as they are supposed to, even when the boiler or water heater seems to be working correctly. When a pump fails, it may work only intermittently or stop working at all. By listening carefully, you can usually hear that the pump is not running, even when the thermostat is set at a high temperature.

Some systems have a single pump that circulates water through all the individual zones of the system, while other systems are designed with individual pumps that serve each zone. Either way, it's not uncommon to eventually need to replace a circulating pump.

Replacing a circulating pump is not a difficult job, but it does require some basic wiring and plumbing knowledge. The technician (or a skilled DIYer) generally begins testing wires for current to rule out problems with wire connections or the power supply.

If replacement is necessary, the project begins with shutting down the water heater and power supply and then isolating the section of tubing served by the pump by shutting off water valves. Then, circuit wire connections to the pump are detached, and water is emptied out of the section of tubing served by the pump. Next, the faulty pump is unbolted and removed, and the new pump is inserted and bolted into place. Finally, the power supply is reconnected, and the PEX tubing is refilled and repressurized.

Replacement of a circulating pump is a project for a professional or a very experienced and knowledgeable DIYer.

3. There is water leaking from the floor tubing.

3. There is water leaking from the floor tubing.

If installed correctly, the PEX tubing that circulates water from the boiler through the heating zones is usually quite trouble-free, but when problems do occur, they can be very serious.

On rare occasions, the hot water tubing that loops below the floor can develop a leak. This most often occurs when flooring installers inadvertently puncture it with a nail, but it can also occur if the original tubing installation was done incorrectly. When radiant floor tubing gets punctured, it is usually dramatically obvious, as water seepage will cause damage to flooring or to ceiling surfaces below the tubing.

Depending on how the tubing was laid, repairs can require removing the flooring, chipping out the mortar bed and then cutting and replacing the damaged section of tubing. It's a major, fairly time-consuming process that is best done by a radiant floor professional or plumber. It's not a repair most DIYers are prepared to tackle.

4. The thermostat isn't connected or is malfunctioning.

4. The thermostat isn't connected or is malfunctioning.

Looking to the thermostat is usually the first step when troubleshooting a radiant floor heating system, as it is the most common source of problems.

The thermostats that control the zone valves in a hydronic radiant floor heating system are usually low-voltage thermostats. They are quite similar to those used in traditional forced-air HVAC systems, but they often use a special design that includes a floor temperature sensor as well as a room temperature sensor. For whole-house hydronic systems, these thermostats also have separate wire connections for each zone valve, allowing you to control the amount of heat sent to different rooms.

Despite these differences, you can troubleshoot and replace the thermostat using the same methods as for any traditional low-voltage thermostat. First, the thermostat is checked to make sure it is properly connected and that it's getting power from its transformer. If these check out but the thermostat is still not sending signals to the zone valves, power is shut off to the system and then the old thermostat is removed and swapped out with a new one that has the appropriate features for the type of hydronic radiant floor heating system you have.

Replacing a thermostat is a fairly easy DIY project, but it is important to buy a thermostat designed for a hydronic floor system and to precisely duplicate the wire connections when installing the new one.

5. The heat goes on and off.

5. The heat goes on and off.

A faulty zone valve is a very common repair, and it is usually the first component checked after problems with a thermostat are ruled out. When a zone valve fails, the zone served by that valve may ignore the signals sent from the thermostat. If the valve fails to fully open, the floor will not warm up sufficiently. If the valve fails to close correctly, the floor may continue to circulate heat, ignoring the shutoff signal from the thermostat. It can be a difficult problem to identify since a zone valve that is beginning to fail may work fine one moment and then fail to work at intermittent intervals.

A professional serviceperson always begins by making sure the wire connections and power supply are intact on the zone valve. If these check out, the technician will proceed to replacement. This involves first shutting off the power supply and disconnecting the low-voltage electrical connections on the zone valve. Next, the technician shuts off water to the system and uses wrenches to disconnect the valve from the manifold.

The new valve is then threaded into place, the water supply is turned back on and the zone is filled and pressured. Finally, the low-voltage connections are reestablished, and the system is turned on and tested.

Zone valve replacement requires some basic wiring and plumbing skills, but a moderately skilled and knowledgeable DIYer can easily do it.

Problems With Electric Floor Heating

Problems With Electric Floor Heating

If you have a bathroom or other limited space with flooring heated by radiant heat, you most likely have an electric radiant floor heating system. This uses a 120- or 240-volt circuit and a wall thermostat that sends electricity to heating cables sandwiched between the subfloor and the finished floor covering. Each room usually has its own independent system controlled by its own line-voltage thermostat mounted in the wall, though a single circuit of sufficient amperage may heat multiple rooms.

These electric radiant heating systems are quite simple in design. Household current heats underfloor wires through simple resistance and is controlled by a basic thermostat. However, these systems can be prone to problems if installed by a DIYer who does haphazard work.

When compared to hydronic radiant floor systems, electric radiant floor systems are extremely simple. Virtually all problems occur because of an interruption of current flow. This interruption of current can occur at any point in the system, and the challenge is to identify where the interruption occurs in order to correct it.

Warning

Repairing problems with an electric radiant floor heating system requires good skills and a good understanding of electrical systems. Don't try to do it yourself unless you feel confident that your DIY skills approach the expert level.

7. There is a circuit problem.

7. There is a circuit problem.

A circuit problem may cause the circuit breaker to repeatedly shut off. If the tripping is caused by a short circuit in the system, the electrician may do diagnostic work to determine where the circuit interruption is occurring. It's also possible the problem lies with a bad circuit breaker that needs to be replaced.

8. The thermostat is faulty.

8. The thermostat is faulty.

Another likely problem is a faulty thermostat that is preventing current from reaching the heating cables running below the floor. Thermostats for radiant floors are line-voltage thermostats carrying full circuit voltage, so replacement requires shutting down the circuit entirely.

9. There are cold spots on the floor.

9. There are cold spots on the floor.

Finally, a break in the resistance cables running below the floor may cause the current interruption. For example, in a large room, you may find that a certain area of the floor no longer warms up properly — likely the result in a break in the continuity of the heating cable. Fixing the problem involves removing the surface flooring and then replacing the damaged section of the electric mat. This can be relatively easy if the mat has been taped down to the subfloor beneath carpet padding or on cork underlayment beneath a floating laminate flooring, but it can be a major project if the mat has been embedded in a layer of mortar or thinset adhesive under ceramic tile.

References

- Heavenly Heat: Common Problems Associated With In-Floor Radiant Heating Systems

- Advantage Airtech Climate Care: Common Problems With In-Floor Radiant Heating

- Warmly Yours: Troubleshooting the Most Common Floor-Heating Issues

- HeatTech: 4 Common Issues with Electric In-Floor Heating Systems and How to Avoid Them

- Radiantec: Radiant Floor Heating Installation Manuals