Tips For Silencing Noisy Furnaces And Ductwork

We may receive a commission on purchases made from links.

It's normal to hear a furnace kick on and air blow through the registers around your home. However, excessive whistling, banging and humming sounds emanating from your ductwork, furnace or air conditioning system could point to trouble.

In some cases, fixing a noisy furnace is something homeowners can confidently DIY. Other issues warrant calling in a pro. If you're nervous about maintaining your furnace, don't hesitate to call in an HVAC technician to show you what to do. Performing an annual furnace tune-up is highly recommended and can alert you to minor problems before they become expensive dilemmas.

Understanding How a Furnace Works

Understanding How a Furnace Works

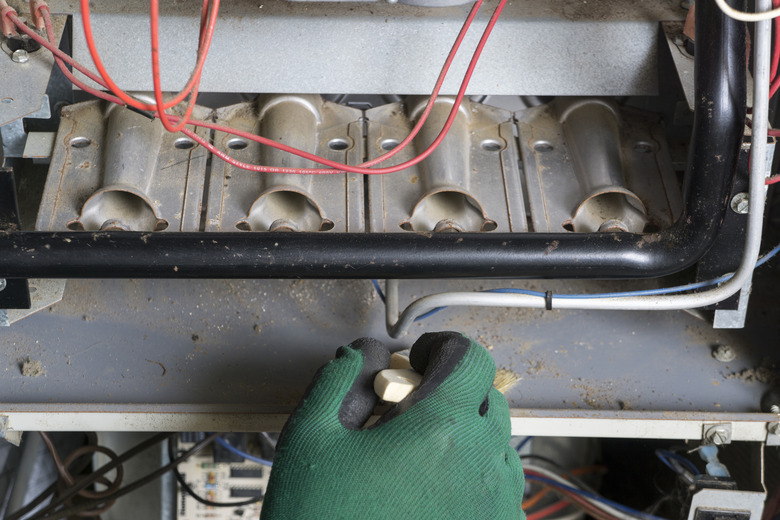

Without a basic understanding of how a furnace works, it's hard to know which parts to order or which maintenance instructions to follow. When looking at a typical gas furnace, you can trace the path of the air from the bottom up. The duct connecting to the bottom of the furnace is the return duct. A filter separates this duct from the furnace to prevent dirt, hair and other debris from clogging the machinery.

Inside the furnace, a blower pulls air from the return duct and pushes it up over the heat exchanger. From there, the warmed air is pushed upward and into the supply vent, which disperses the air throughout your home.

You'll see plenty of other little boxes and wires inside the furnace, but only one other contraption has the potential to make noise: the capacitor, which sits next to the blower motor and gives it a boost of power to ensure it operates efficiently.

Whistling: Filter or Ductwork

Whistling: Filter or Ductwork

If you hear a whistling sound every time the furnace kicks on, the air is meeting some resistance as it flows through the air ducts and out into your home. The most common cause of this resistance is a dirty filter. With too much dust clogging the filter, air can't pass through. It whistles as it goes by.

The furnace filter is located right behind a large return vent in the wall or ceiling or right next to the furnace itself. Remove the vent cover or filter cover (they usually have tabs you can rotate by hand to unlock) and slide out the filter. Purchase a new filter with the exact same style and dimensions and install the new filter. If the whistling continues with a brand-new filter, the mesh may be woven too tightly. Try installing a filter with larger mesh fabric for better airflow. For example, if the air filter has a MERV rating of 12, try another filter with a rating of eight or 10.

Furnaces can also whistle if there's no filter installed at all. Having no filter also means dirt and grime can clog the inner workings of the furnace, which can cause other furnace noises that are far more costly to fix. Finally, check the ductwork seams to make sure they're sealed with tape or mastic. If these seals are ripped, crumbling or nonexistent, the ducts may whistle as air escapes through the joints.

Whistling: Ductwork Dampers

Whistling: Ductwork Dampers

You've installed a clean filter, and the heating system continues to whistle. It's time for Plan B: Check your return and supply ducts for dampers. Not every furnace features dampers, but you'll know you have them if you see a peg sticking out of the supply ducts where they branch in different directions. Some dampers are motorized, so instead of a peg, you'll see a little box about the size of an electrical outlet protruding from the ducts.

Dampers increase the efficiency of your HVAC system by preventing warm air from going somewhere it isn't needed. Motorized or automatic dampers connect to a thermostat and only open when the thermostat detects a drop in temperature. These can whistle when air pushes forcefully against the dampers and leaks through the flaps. Manual or nonmotorized dampers open whenever there's sufficient pressure in the system to open them, and these can whistle if friction prevents them from opening correctly.

Whistling manual dampers just need to be lubricated. A dry lubricant is recommended to avoid attracting dust or causing rust buildup. Whistling motorized dampers require a relief valve, which consists of a pipe installed between the return and supply ducts with a manual damper in the middle. When pressure builds up too high against the motorized dampers in the supply duct, the air diverts through the pipe, pushes open the manual damper and exits to the supply duct. If you've never installed HVAC ductwork, consider calling in a pro for this task.

Scraping or Rattling: Blower Wheel

Scraping or Rattling: Blower Wheel

If you hear a metallic scraping, grinding or rattling sound, the culprit is most likely the blower wheel. Turn off the system and take off the cover to the furnace. The blower wheel looks like a large metal drum tipped on its side, sort of like a hamster wheel. It's located at the bottom of the furnace assembly.

Note that the blower wheel rotates around a center arm or shaft and is held in place with a setscrew. This screw can come loose over time, allowing the blower wheel to wiggle around just enough to make a clunking or scraping sound as it turns. Use a wrench to tighten this screw.

While you're inspecting the blower wheel, make sure it's dust-free. Dirt that collects on the blower wheel can also cause odd sounds and shorten the furnace's life span. Wipe it down with a damp cloth before turning the system back on.

Vibrating or Idling Sound: Motor Bearing

Vibrating or Idling Sound: Motor Bearing

Bearings allow metal parts to move around each other with minimal friction and the subsequent grinding sounds and heat created by friction. Bearings are found in both the blower motor and the inducer motor in your furnace. When they fail, your furnace will start to sound like an idling car. It may also sound or feel like it's vibrating.

Although the noise you hear sounds quite drastic, there may be a simple temporary solution: lubrication. While most newer furnaces have motors with sealed bearings, older furnaces often have motors that can be oiled, indicated by one or more oil ports on the motor housing. It's a good idea to lubricate furnace motors annually to keep them working smoothly. Simply remove the cap to the oil port and add about two drops of lubricating oil designed for motors.

Squealing: Drive Belt

Squealing: Drive Belt

Some furnace motors feature a drive belt. This piece of smooth rubber efficiently transfers power throughout the system; one pulley moves the drive belt, which then turns another pulley. Instead of having a unique power source for every pulley, the drive belt acts as a go-between. Drive belts only work if the rubber is in good condition (i.e., not cracked) and has appropriate tension. It will start squealing, hissing or whistling if it becomes brittle or loose.

To inspect the drive belt, turn off the system and press down on the center of the drive belt where it spans across the two pulleys. It should only give about 1/2 to 3/4 inch. Any movement beyond that range indicates that it's too loose. Inspect the entire length of the belt for any noticeable signs of weakness or decay. Conduct a sniff test too; a burnt rubber smell is never a good thing.

Drive belt pulleys also need to be properly aligned for the belt to smoothly travel over them. The pulleys are secured to shafts with a setscrew, and this can become loose over time, causing the pulleys to shift. Tightening a loose drive belt also involves tightening motor bolts. Due to the numerous variables affecting proper drive belt function, leave this fix to the pros if you aren't sure how to do it yourself.

Popping or Banging: Ductwork or Heat Exchanger

Popping or Banging: Ductwork or Heat Exchanger

Popping or banging sounds could be benign or very serious. In the best-case scenario, the banging sound is the result of warm air pushing against the thin walls of metal ducts, popping them out slightly. The ductwork may be too narrow for your needs, or the fan speed may be too high. Otherwise, there's really nothing that can be done about this common and normal sound.

However, if the popping sound doesn't have a telltale metallic twang, it could be emanating from the heat exchanger. That's when you should call a pro. The popping could indicate that the heat exchanger has cracked or will soon crack. You can tell if the exchanger has already cracked because it will produce moving yellow flames instead of stable blue flames.

Either way, a popping heat exchanger means there's a risk of a natural gas or carbon monoxide leak or there will be in the near future without intervention. Call an HVAC pro as soon as possible.

Humming or Screeching at Startup: Capacitor

Humming or Screeching at Startup: Capacitor

If you're running the air conditioning unit in particular and hear a humming or screeching sound only when the cold air kicks on, the compressor is struggling. If it's winter and you're running the furnace, the blower and inducer motors are struggling instead. However, it's not actually the compressor or motors that need to be replaced; it's the capacitor.

Capacitors weaken over time, supplying less and less start-up energy to the motors and compressor. As these parts struggle to chug along, they produce a humming or screeching sound. Left unchecked, your furnace or air conditioner could stop working altogether until the capacitor is replaced. The motors and compressor are also in danger of wearing out quicker under such conditions.

Because it involves working with electricity, call a pro to install a new capacitor in your furnace.

Continuous Humming: Dirty or Loose Parts

Continuous Humming: Dirty or Loose Parts

Humming or screeching that lasts the entire time the furnace runs could mean the equipment is dirty. If you open the furnace cover and think, "Man, when was the last time anyone vacuumed this thing?" it's beyond time for a cleaning. Dust and dirt clog up mechanical parts, increase friction and make the motors work harder to compensate.

Turn off electricity to the furnace, shut off the gas line and make sure the furnace is cool. Note where the hot surface ignitor is located on your system and make a mental note not to touch this very fragile piece. Then, tackle the rest of the furnace with a shop vacuum. Flush dirt from tiny nooks and crannies using compressed air. If needed, use a damp cloth to wipe dirt from surfaces.

Finally, make a note on your calendar every three months to replace the furnace filter, as a dirty filter makes it easier for dirt to get trapped inside the furnace. Check it more often if you have a large household (everyone produces dust!) or shedding pets.

References

- YouTube: Twintech Heating and Cooling – Furnace Noises and What They Mean

- Snell Heating & Air Conditioning: 7 Types of Loud Furnace Noises & How to Fix Them

- YouTube: RepairClinic.com – Furnace Noisy Or Loud — Furnace Troubleshooting

- YouTube: AMRE Supply – Noisy Furnace? – Top 5 Fixes | Repair and Replace

- Jackson & Sons: Talking HVAC: What a Humming Air Conditioner is Saying

- Romaniuk: Signs Your Furnace Heat Exchanger May be Cracked

- YouTube: Tec Tube – Fan Belt Alignment & Tension