A Homeowner's Guide To Saw Blades

From jig saws to chainsaws, there's a wide range of saw blades to choose from, selecting the right one may feel daunting. To focus your search for the right blade, begin by asking yourself a few simple-to-answer questions:

- What type of material do you want to cut?

- What type of saw do you need a blade for?

- If it's a power saw, how powerful is it and what size blade does the manufacturer recommend?

Anatomy of a Saw Blade

Anatomy of a Saw Blade

First, you'll find it helpful to know some terminology.

- Size: The diameter of a circular saw blade, for example, or the length and width of a bandsaw blade.

- Teeth: The part that cuts, teeth are sometimes measured as teeth per inch, or TPI. Generally speaking, blades with more or finer teeth yield a smoother cut, while blades with fewer or larger teeth remove material faster and more aggressively but leave a rougher cut. So why might it be better to use a blade with fewer teeth for some projects? Because the more teeth a blade has, the slower the cut rate and the more friction and heat it generates. Teeth may be tipped with carbide, diamond, silicon carbide, or aluminum oxide.

- Tooth configuration: The shape of the teeth and the way they're grouped affects how the blade cuts and whether, for example, it works best for ripping, crosscutting, or laminates.

- Gullet: The curved space in front of each tooth.

- Kerf: The thickness of the blade, and therefore the width of the cut.

- Rake angle: The angle between the face of the tooth and an imaginary line drawn from the center of the blade. Steep angles between 18 and 22 degrees rip and cut softer materials more effectively. Shallow angles are best for hard materials.

What Material Do You Want to Cut?

What Material Do You Want to Cut?

Depending on a combination of the number of teeth, their configuration, and the material the blade is made from or its teeth are tipped with, saw blades can cut different materials.

Wood

Wood is what most of us are cutting most often, so there are many saw blade choices. Depending on their tooth design, some blades are better at cross-cutting (sawing perpendicular to the grain) while others excel at ripping (cutting parallel with the grain). Combination blades can do both tasks and are more convenient for basic DIY.

Here are typical uses for tooth counts on blades for wood:

- 16 to 24 teeth: For demolition/framing

- 32 to 50 teeth: For all-purpose cutting

- 60 to 80 teeth: For finish grade

- 100 to 140 teeth: For fine finish and cabinetry

Masonry and Tile

Sawblades for these materials can have smooth edges with no teeth, and there are fewer options to choose from. You'll find inexpensive, short-lived blades called cutoff or abrasive wheels, as well as long-life diamond-tipped blades. Segmented and continuous rim blades are usually diamond-tipped. They can be used wet or dry; wet cutting keeps the blade cooler and therefore extends its life.

- Cutoff wheels: Inexpensive abrasive wheels well-suited for grinding and minor cutting. They're made of an abrasive composite that consumes itself by grinding down as you cut.

- Segmented blade: These long-lasting blades are perfect for rough cutting when a smooth finish is of no concern.

- Continuous rim: For fine-finish cutting of tile and granite.

Metal

With a combination of teeth like those on wood-cutting blades and the cutoff wheels used on masonry, metal blades are more expensive. The tooth count on metal blades starts higher than for wood; the fastest cutting blades are in the 38-teeth range, and the finer blades are 60 to 80 teeth.

- Cutoff wheel: This inexpensive abrasive disk for basic cuts on thick metals wears out quickly. Because it's brittle, keep this type of wheel in a protective case when not in use.

- Carbide blade: A durable blade that cuts through thick or thin metals of any type.

PVC and Laminate

Look for blades specially designed to cut these materials.

Blades for Circular Saws, Miter Saws, and Chop Saws

Blades for Circular Saws, Miter Saws, and Chop Saws

When choosing a circular saw blade, it's crucial to make sure it fits your model of saw. The face of the blade will be printed with the blade's size, arbor hole size, kerf, the number of teeth, and the revolutions per minute (RPM).

Make sure that the hole in the center of the blade (the arbor hole) fits the shaft (or arbor) on your saw. (Be aware that many blades with round arbor holes have an insert you can knock out to end up with a diamond-shaped arbor hole, in case your saw has a diamond shaft.) Also, make sure the rating of maximum RPMs on the blade is compatible with your equipment.

Here are some general guidelines, but check your owner's manual:

- Handheld circular saws: These use 4 1/2- to 7 1/4-inch blades, and they're usually carbide-tipped.

- Tile saws: These take 7- or 10-inch diamond-tipped blades.

- Compound miter saws: Like handheld circular saws, these are usually carbide-tipped blades, but much larger—10 to 12 inches. Choose blades with 60 teeth and a 2° negative rake for smooth miter cuts.

- Chop saws: These are for cutting metal, and are also known as cutoff saws or abrasive saws. They use silicon carbide or aluminum oxide-tipped abrasive blades 14 inches in diameter.

Beyond that, as explained earlier, different saw blades are designed to cut specific materials.

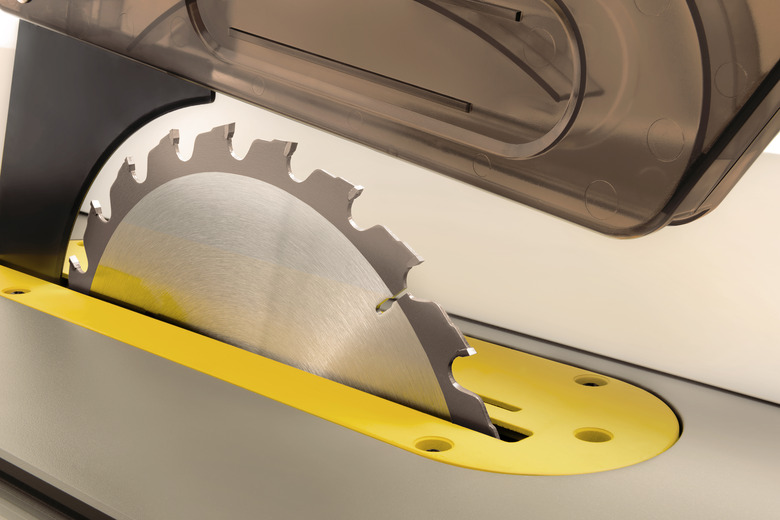

Blades for Table Saws

Blades for Table Saws

Typically available in sizes ranging from 10 to 12 inches, the four basic blade types for table saws are determined by the shape, or grind, of the teeth.

Flat top grind (FTG) blades. The top edge of the teeth of flat top grind (FTG) blades are square to the saw plate. Also called rakers, these teeth cut fast and are durable, but they don't produce a clean cut. They're designed to rip. A 24-tooth FTG blade is good for ripping quickly, but it won't cut very smoothly.

Alternate top bevel (ATB) blades. The top edge of the teeth on alternate top bevel (ATB) blades are angled, with every other tooth "leaning" in the alternate direction. This helps the blade shear wood cleanly. The steeper the angle, the cleaner the cut, but the quicker the blade will dull. Forty-tooth ATB blades are sold as all-purpose blades that excel at clean crosscuts and miters. Most crosscutting blades have 60 to 100 ATB teeth, since the more teeth, the cleaner the cut will be. Use an 80-tooth ATB blade for concerted crosscutting, mitering, or sawing of delicate sheet goods such as plywood, particleboard, MDF, hardboard, plastic laminate, and melamine.

Combination (ATBR) blades. This type of blade will save you the trouble of switching from a rip blade to a crosscut blade. Combination blades have 50 teeth arranged in sets of five, each containing four ATB teeth followed by a raker. The ATB teeth crosscut cleanly while the rakers rip, so combination blades are considered all-purpose blades. A 40- or 50-tooth all-purpose or combination blade rips and cross-cuts well and yields a cleaner cut than a 24-tooth blade. It works well for most of the work a home DIY-er will put it to, but it doesn't feed as fast as a rougher cutting 24-tooth blade.

Triple-chip grind (TCG). The teeth on a triple-chip grind (TCG) blade alternate between a raker tooth and a chamfered tooth. The chamfered tooth roughs out the cut, and the raker cleans it up. This blade is ideal for sawing dense materials such as plastic laminate and Corian, and non-ferrous metals such as brass or aluminum. Plastic laminate is quite dense and is tough on ATB teeth, so if you frequently work laminates, invest in a TCG blade. Otherwise, your ATB blade will soon require a trip to the sharpener.

Blades for Reciprocating Saws

Blades for Reciprocating Saws

Reciprocating saws have the power to muscle through metal, masonry, stucco, fiberglass, composites, wood, drywall, and more—but it's important to have the right blade for the material. The TPI, which ranges between 3 and 24, determines the material the blade can cut. Blades with a low TPI are good for wood, while those with a high TPI are good for metal. Try to keep at least three teeth in contact with the material at all times. This means that thinner materials call for blades with a greater TPI count.

Blades for reciprocating saw range from 3 to 12 inches long, as well as in a variety of widths. Choose wider, thicker blades to reduce bending and wobbling. Heavy-duty blades are typically 7/8 inch wide and 0.062 inch thick. Blades with a thickness of 0.035 inch thick are adequate for standard cuts, while blades with 0.05 inch thick have better stability. Choose short blades with tapered backs for plunge cutting.

Blade composition also varies for reciprocating saw blades. Carbon steel blades bend without breaking, so they're well-suited to cutting wood and plastic. High-speed steel blades have durable teeth, but they're more likely to break. Bi-metal blades combine high-speed steel teeth with a carbon-steel body, resulting in a heat-resistant, flexible blade that resists breaking and lasts longer than other blades. Use carbide-grit blades for ceramic tile, fiberglass, and cement board. These are generally high-speed steel or carbon steel blades with carbide grid impregnated on the cutting edge.

Blades for Band Saws

Blades for Band Saws

Band saw blades are sold by length, which varies by saw; consult your manual. You can choose from a variety of blade widths (measured from tooth to opposite edge), TPI and tooth configurations, as well as material—carbon steel, bi-metal, and carbide.

Whether you're using a portable band saw or a stationary one, if you're cutting straight lines, go with the widest blade the machine can tension correctly, usually 1/2-inch for mid-size saws. Use narrower blades for curves; the tighter the radius you need to cut, the narrower the blade will have to be. A 3/8-inch blade can cut a radius of about 1 1/2 inch, while a 1/8-inch blade can manage a smaller radius of about 1/8 inch.

The basic tooth styles include regular, skip, and hook. Regular tooth blades are a general-purpose blade; their proportionally spaced teeth do both cut-off and contour sawing well, and they can saw thin materials. The teeth on skip tooth blades have more widely spaced teeth with a rake angle of 0° that prevents clogging, making this blade ideal for plastics, non-ferrous metals, and soft woods. Hook tooth blades, which are commonly used for thicker wood, hardwood, metal, and plastic, have larger teeth and deeper gullets with a positive rake angle of 10° so the blade feeds into the material more aggressively and cuts faster.

Blades for Jigsaws

Blades for Jigsaws

Standard jig saw blades with a TPI of 8 to 10 can cut almost any type of wood. The teeth on a standard blade point up, meaning the saw cuts on the upstroke. Reverse blades cut on the downstroke, and are meant for cutting materials with a finished surface—laminate countertop, for example, or finish plywood. Blades come in different lengths and widths. A blade 3/8 inch wide can handle shallow curves, but choose one 1/4 inch wide for tight curves.

Blades for Hacksaws

Blades for Hacksaws

The thin, interchangeable blades for hacksaws range from 14 to 32 TPI.

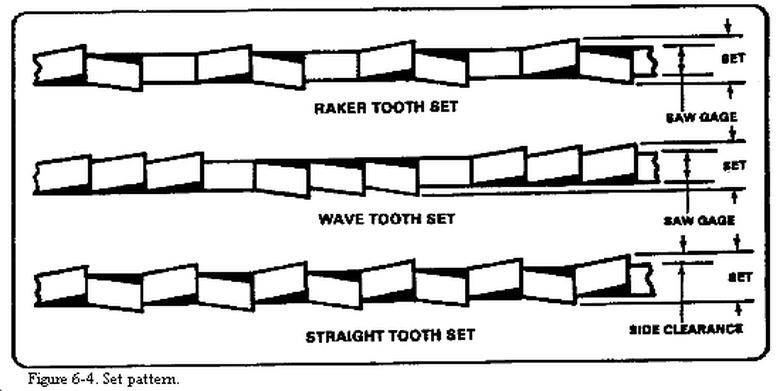

Raker hacksaw blade. The teeth are arranged in angled sets of three, a configuration that makes cutting standard metal pipes easier.

Regular set hacksaw blade. Its teeth are positioned next to one another without spaces, but every other one goes at a different angle, either forward or backward, which is ideal for cutting soft materials such as PVC.

W**avy set blade.** The teeth are arranged next to one another but with a slight wave from one side to the other. Choose this blade for cutting thin metal, such as metal ducts.

Blades for Scroll Saws

Blades for Scroll Saws

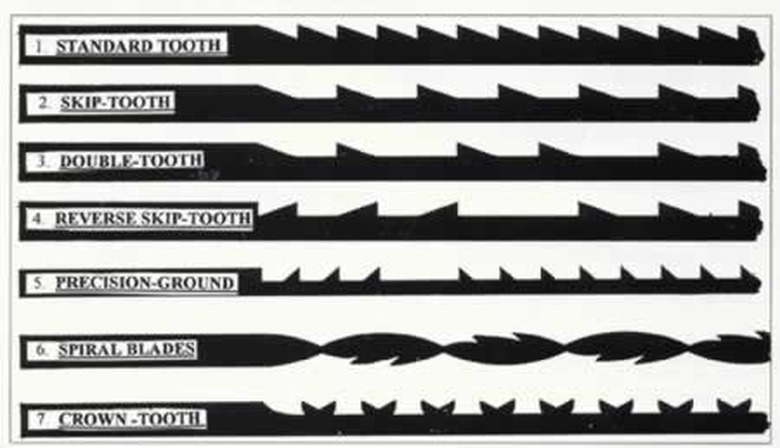

You'll find two major categories of scroll saw blades—plain end or pin end. Pin-end blades are thicker and wider, and because they won't fit through a small hole, they're not good for intricate cutting. Within those categories are different types:

Standard tooth blades. The teeth are all the same size and distance apart, and among them are blades intended for cutting wood and those for metal. Wood blades have larger teeth than metal ones, with more space between them.

Skip-tooth blades. In these blades, every other tooth is missing. The gullet is much wider, which keeps the blade cooler during cutting.

Double-tooth blades. Similar to a skip-tooth blade, but with a large gullet between sets of two teeth. These leave a very smooth cut, but they cut more slowly.

Reverse skip-tooth blades. Much like a skip-tooth blade, except the teeth on the bottom half of the blade point up. This prevents tear-out or splintering on the bottom of the cut and makes the blade ideal for cutting plywood. When installing the blade, clamp it in such a way that only two or three teeth point up above the table top when the saw arm is in the highest position; this may require trimming off some of the bottom of the blade.

Precision-ground blades. These are skip-tooth blades with small teeth ground to shape rather than filed, making them much sharper so they cut in a straight line and leave behind a very smooth cut.

Spiral blades. These have teeth all the way around, letting you cut in all directions without turning the work. They leave a very rough, wide cut, can't cut tight or sharp corners, and tend to stretch.

Crown-tooth blades. With pairs of teeth pointing in opposite directions with a space between each set, the blade can be mounted in the scroll saw in either direction. They cut a little slower than regular blades, but do a good job of cutting plastic and Plexiglas. When the blade dulls, flip it around to use the other side.

Other specialized blades exist for cutting plastic, metal, and glass.

Blades for Coping Saws

Blades for Coping Saws

Although various coping saws have different-sized throats (the span between the blade and the frame), ranging from 4 to 6 inches, all coping saws use the same blades, measuring 6 3/8 to 6 1/2 inches long. You'll find blades intended for use with metal, tile, wood, and plastic.

High-carbon steel. Blades made from high-carbon steel are for straight cuts through thin sheets of nonferrous metal or nonhardened steel.

Tungsten carbide. For making precise, curved cuts in ceramic tile, blades made of tungsten carbide steel are best.

Helical teeth. These blades slice through plastic, solid surfacing, and soft clay tiles. The blade cuts in all directions; it requires only a shift in pressure to make sharp turns.

Coarse blades of 15 TPI or less go through wood quickly. Fine blades with 18 TPI or more can make tight curves, but they cut more slowly.

Blades for Chainsaws

Blades for Chainsaws

To choose a saw chain, you need to know the pitch, the gauge, and the number of drive links. The chain saw bar should have pitch and gauge displayed on it, and possibly the number of links. Once you have these facts, your choice is based on what you prefer.

Low-profile cutters. There are hundreds of saw chain styles, but most small consumer chainsaws come with this style of chain, which has a rounded radius edge and grind profile. These are easy to resharpen by filing.

Semi-chisel cutters. These also have a round radius edge, but with a round grid edge. They cut more slowly than chisel chains, but often stay sharper for longer. They are ideal for cutting soft woods. They're very easy to file and tolerate sharpening inaccuracies well.

Full-chisel cutters. With square radius edges and round grind profiles, these saw chains are ideal for cutting hardwood. Although they cut all types of wood faster, they dull more quickly and require regular sharpening. Although relatively simple to file, they don't tolerate sharpening inaccuracies.

Square-chisel cutters. This specialty class of full-chisel cutters is normally used by professionals.

Blade Maintenance

Blade Maintenance

Follow a few guidelines to get better results and a longer life from your blades.

Protect the teeth. Saw blades can chip or break when dropped or knocked against other tools. Be careful when installing blades. Store them in such a way that they don't come into contact with other blades or bits.

Keep the teeth clean. Saw blades withstand a huge amount of heat and stress during cutting, and dirt and gum build up on their surfaces. Remove build-up with a blade cleaner.

Keep the teeth sharp. When you feel the feed resistance of circular saw blades increase or see that the quality of the cut has deteriorated, take the blade to a professional for sharpening. If you try to sharpen them yourself, you risk spoiling the cutting geometry of the blade.