What Is Underlayment?

The support and solidity of your floors comes from the framework of joists that form the basic skeleton along with the subfloor, which spreads out the weight of furniture and human activity over multiple joists. The beauty and much of the comfort of your floors results from whatever decorative flooring you choose. But flooring products often have special requirements that your subfloor can't supply. That's when it's necessary to provide a transitional layer called the underlayment.

Each kind of decorative floor treatment has its own set of installation specifications and each is best served by a different kind of underlayment. Underlayment can offer a moisture barrier, smooth out slight irregularities in the subfloor, add cushioning to the floor treatment above, quiet a noisy floor, and isolate an inflexible flooring like ceramic tile from the more dynamic wooden subfloor.

For many types of flooring, there are multiple grades of underlayment from which to choose, even after the basic requirements have been met. More expensive underlayment products may offer better performance, more comfort and greater longevity. The extra money you spend on better underlayment often translates to extra protection for your flooring investment.

In some instances, the existing flooring material can effectively serve as the underlayment for new flooring material. For example, an existing resilient vinyl floor or cork floor that is in good shape can be an excellent underlayment for new wood or laminate floors. And it is often fine to install a new layer of sheet vinyl directly over an existing sheet vinyl floor. Always check the manufacturer's specifications, though, for details on what underlayments are acceptable. Also, adding new flooring materials over old may increase the overall thickness of the floor, creating problems with thresholds and door clearance. In these cases, tear-out of the old floor and installation of a new underlayment is the logical approach.

Underlayment for Carpeting

Underlayment for Carpeting

When carpeting is your floor treatment preference, it would seem that your choice of underlayment is simple: some sort of cushiony pad. However, carpet pads are manufactured from a variety of rubbery materials. Some incorporate better moisture resistance, which can be crucial in certain environments and circumstances. Some kinds of foam pad can deteriorate and crumble after a few years. High quality "memory foam" underlayment, on the other hand, can last for many years and can even make an inexpensive carpet feel and perform like a much higher-quality product.

Underlayment for Laminate Flooring

Underlayment for Laminate Flooring

Although many flooring products are engineered with a laminating process that bonds together layers of material, the product known officially as laminate flooring is a particular type of flooring that usually includes four layers: backer layer; core layer of fiberboard; a photo print layer that allows the flooring to mimic hardwoord, ceramic tile or other materials; and a clear surface wear layer made of aluminum oxide or a plastic-like material. These floors typically "float" over the subfloor, with planks held together at the edges by a "click-lock" tongue and groove system.

Retailers that sell laminate flooring products usually offer two or three grades of underlayment to go beneath. Materials can range from thin resilient foam to thin layers of cork. Rolled out in long strips and taped at the seams, this additional underlayment is especially important in below grade applications where a moisture barrier is necessary to protect the flooring from warping or swelling. The thicker underlayment options add subfloor insulation and greater resilience to the floor, and the additional thickness evens out minor irregularities in the underlying subfloor.

Underlayment for Wood or Bamboo Floors

Underlayment for Wood or Bamboo Floors

The decision to install a hardwood floor is presumably a longer-term and more permanent choice than opting for a floating laminate floor or carpeting. That makes it especially critical that the underlayment conforms to precise specifications when it comes to moisture protection. Excess moisture trapped beneath hardwood floors can cause warping and deterioration. At its most basic, suitable underlayment for wood floors can be simply a layer of asphalt-treated paper. For a more premium treatment, thin cork underlayment provides superior noise control and cushion.

Some wood and bamboo flooring products are not solid wood, but are instead engineered wood products in which a surface layer of genuine hardwood is bonded (laminated) to one or more core layer layers of plywood or MDF. These wood floors are installed by joining the planks with a modified tongue-and-groove system, and they often "float" over the subfloor instead of being nailed down. With this kind of engineered hardwood or bamboo flooring, the proper underlayment is the same as that for floating laminate flooring—some kind of thin resilient pad made of foam. Some underlayments have a built-in moisture barrier bonded to the foam—make sure to choose the type of underlayment appropriate for your installation.

Underlayment for Vinyl or Linoleum Flooring

Underlayment for Vinyl or Linoleum Flooring

If you are putting in sheets or tiles of vinyl or linoleum flooring, the typical underlayment choice is 1/4-inch lauan plywood. When the plywood is installed, take special care to fill any irregularities, seams and nail or screw indentations. These are resilient flooring materials, and you will be surprised how even the slightest imperfection can telegraph its presence through the flooring. In addition to glue-down sheet flooring, there is a class of vinyl flooring that is perimeter-bonded only. That means it is glued only around its edges and it "floats" in the center, making it less apt to transmit flaws in the underlayment.

A new class of vinyl flooring, known as luxury vinyl flooring (LVF) usually comes in click-lock planks. This flooring often looks remarkably like wood, ceramic tile, or other natural products, but the planks are somewhat flexible. Luxury vinyl flooring requires the same underlayment treatment as for standard sheet vinyl or tiles.

Underlayment for Cork Flooring

Underlayment for Cork Flooring

Cork flooring comes is several forms, with the most common being glue-down tiles, which are laid down in much the same way as glue-down vinyl tiles; and snap-lock "floating" floors that are installed similar to the way that laminate flooring planks are installed.

Cork floors are slightly resilient and they will telegraph imperfections in the subfloor through to the surface of the flooring. For this reason, the subfloor surface below needs to be perfectly flat and free of imperfections. Most manufactures instruct that a subfloor in perfect condition can be a suitable base for cork to be installed directly over it, but any subfloor with imperfections is best covered with a subfloor of 1/4-inch or 3/8-inch plywood underlayment first.

Underlayment for Stone or Ceramic Tile

Underlayment for Stone or Ceramic Tile

In terms of underlayment, perhaps the most demanding type of floor covering is ceramic or natural stone tile. That's because there's a basic incompatibility between the wood that comprises most residential subfloor construction and the ceramic material. Wood flexes and can expand when dampened; tile does not. For ceramic tile installation, the function of the underlayment is to create a buffer between resilient wood and rigid ceramic. There are two ways to accomplish that.

The most common underlayment choice for rigid tile is cement backer board. Like the tile, cement board is moisture proof; but because it incorporates fiber into its cementitious mixture, it won't crack like tile or mortar can.

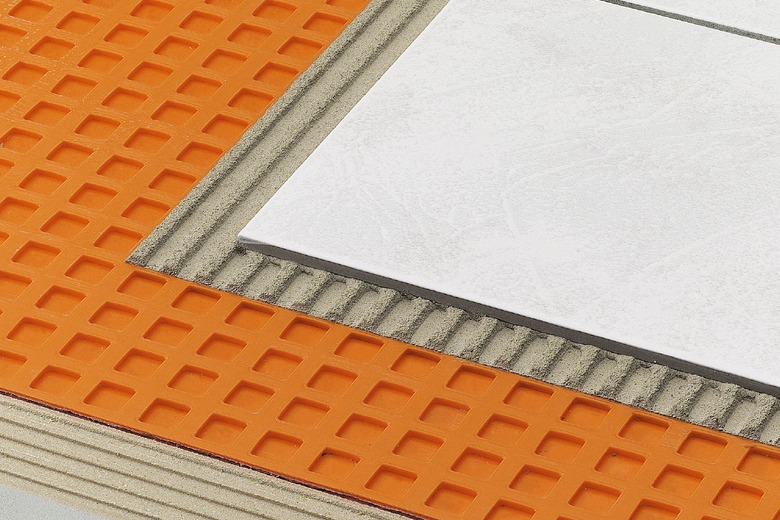

The alternative to cement board as an underlayment for tile is a product called an uncoupling membrane. Commonly known by the name of its most popular brand, Schluter Ditra®, the purpose of an uncoupling membrane is to isolate any movement in the subfloor from the tile and mortar matrix above. Made of polyethylene, Ditra is designed to adhere to tile mastic on the top and mortar on the bottom.

Underlay with Care

Underlay with Care

If you are installing your flooring yourself, discuss with the supplier what sort of underlayment will be best. If you are having it professionally installed, have that discussion with the installer. Be aware that there are choices to be made and those choices can affect your satisfaction with your new floors.