How To Use A Pop Rivet Gun

If you are a DIYer of a certain age, there is a fair chance that back in high school you were introduced to pop rivet guns in industrial arts class. A lightweight tool used to mechanically bind sheet stock (usually metal or acrylic), these friendly fasteners require only a drilled pilot hole and some hand compression to snap off a pop rivet and draw two workpieces together, more or less permanently. They are used most often for ductwork, gutters, metal repair work and crafts.

Until the metalworking industry comes out with a battery-powered spot welder you can buy for ten bucks, a pop rivet gun can do certain things no other tool can manage. Most importantly, this tool offers a legitimate method for joining thin metal stock when you have no access, or limited access, to the backside of the workpieces. This is why pop rivets are sometimes called "blind rivets." The usage is specific, yes, but in the right situation, it is invaluable.

How Do Pop River Guns Work?

How Do Pop River Guns Work?

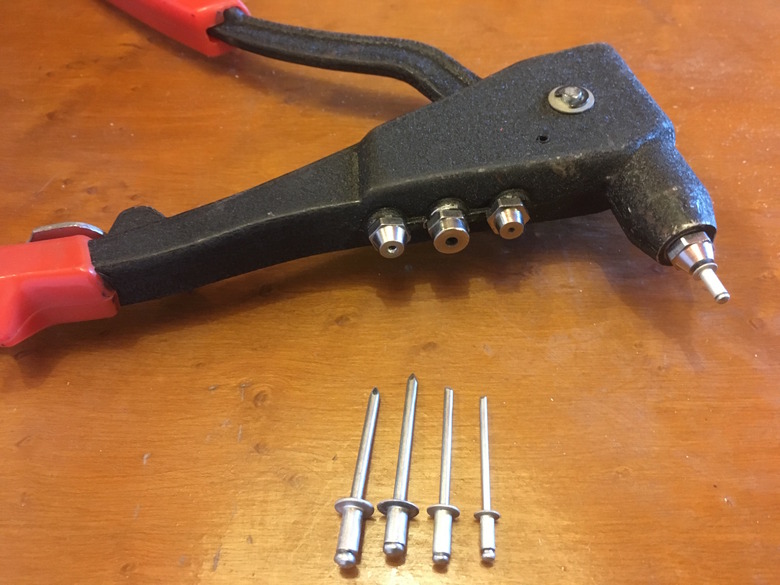

The pop rivet itself is a small fastener, usually made of aluminum, with a malleable head and a steel stem that fits into the throat of a pop rivet gun. You feed the head of the fastener into a guide hole through both mating parts until the flange is flush against the front side of the workpiece, and then you simply squeeze the tool handles together. With each squeeze the "rivet" is drawn up against the backside, compressing and widening in the process. After a few squeezes, the stem breaks loose from the head and you are left with the round flange on the front side and a crumpled up mass of malleable aluminum on the backside, functioning as a nut. Not always pretty—and they do stick out a bit—but the connection is quite sturdy.

Tip

The concept behind a pop rivet is similar to a Molly bolt. Like a pop rivet, a Molly bolt is inserted into a guide hole, generally in a wall or ceiling. Instead of compression, they are activated by screws (or "inclined planes" if you want to take another trip back to high school). In the case of Molly bolts, the screw is tightened, causing the business end of the fastener to expand scissor-style until it has created a broad point of resistance that spreads out behind the wall or ceiling surface and anchors the screw tightly.

How Do I Use a Pop Rivet Gun?

How Do I Use a Pop Rivet Gun?

Using a pop rivet gun could not be easier.

- Align your mating workpieces just where you want them (if you are doing a repair, this likely has been done for you already). A C-clamp or spring clamp is helpful here.

- Select a drill bit (an ordinary metal twist bit works well for either sheet metal or acrylic) the same diameter as the pop rivet head, and drill a guide hole through both workpieces at the joint area. If you are drilling sheet metal, first squirt a little oil on the drilling point of the bit.

- Load the pop rivet into the gun, stem first. Make sure you are using the gun nozzle with an opening diameter that matches your rivet.

- Insert the head of the pop rivet all the way into the guide hole so the flange is flush against the outer workpiece.

- Squeeze the tool handles together. You will feel the resistance increasing as you squeeze. Maintain even pressure and try not to wiggle the tool too much.

- Squeeze until you hear a snap—that noise is the stem breaking loose from the head.

- Remove the stem from the throat of the gun (this can be a little frustrating). Repeat as necessary.

What Can I Use Pop Rivets For?

What Can I Use Pop Rivets For?

Pop rivets have a number of useful purposes around the house:

Craft projects. If you go to craft and DIY websites you will occasionally see some cool projects you can build using pop rivets as primary fasteners- usually these involve attaching metal hardware to other metal surfaces, but pop rivets are also are one of the few ways you can easily join two flat sheets of acrylic mechanically or fasten metallic hardware to clear materials like acrylic.

Repair. Let's say you have a metal desk and one of the metal panels has detached from the frame. This happens a lot. A metal screw will probably strip out if you try and simply screw it back on. You can try a nut and bolt, but in many cases, you won't be able to get your fingers or a tool in to hold the nut while you tighten the bolt. Welding can work, but who wants to do that? A single pop rivet can solve your problem, and it also leaves behind a rather elegant rivet flange that looks much more professional and intentional than a bulky bolt head. And the ugly side is out of view.

Ductwork. Inspect the matrix of cold air returns and heat vents in your basement. Imagine that you want to repair a failed seam or perhaps even attach something to the metal. A pop rivet gun is your answer.

Rivet Options

Rivet Options

Most rivet manufactures sell variety packs containing an assortment of rivets in multiple sizes and materials. These are relatively inexpensive and unless you have a very specific usage in mind, it is good to have a variety of fasteners at your disposal. The pop rivet gun should come with three or four screw-in nozzles to accommodate the standard rivet stem diameters. You just screw in the nozzle that matches your rivet of choice, while the others are stored conveniently in threaded holes in the handle top.

Rivet sizes: For the consumer, pop rivets are pretty easy to find in three categories: light 1/8-inch (3 mm) diameter, medium 5/32-inch (4 mm) diameter, and heavy-duty 3/16-inch (5 mm) diameter. These diameters refer to the thickness of the rivet portion of the fastener. If you dig deep, you can find rivets in each diameter and of varying lengths. Again, the lengths refer to the rivet itself and not the stem portion.

- Short rivets are meant for joining two materials with a combined thickness of up to 1/8 inch (3 mm).

- Medium-length rivets are rated for thickness up to 1/4 inch (6 mm).

- Long rivets are for materials with combined thickness up to 1/2 inch (12 mm).

Because it must shorten during installation, the rivet you choose should be at least as long as the combined thickness of your workpieces, PLUS 1.5 times the diameter of the rivet.

Material: Most pop rives are made of aluminum, which can be used indoors or outdoors. Some aluminum rivets are painted white to blend with white metal gutter or soffit/fascia systems. For greater holding power, choose a steel rivet (indoors only) or a stainless steel rivet—stainless rivets can be used inside or out, but they are costlier than standard steel rivets.