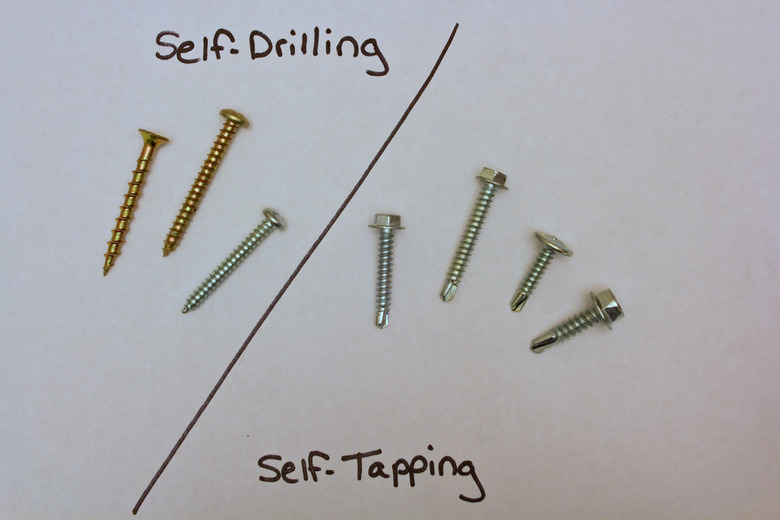

The Differences Between Self-Tapping And Self-Drilling Screws

People often use the terms "self-drilling" and "self-tapping" interchangeably, but they actually describe two completely different types of screws. In some fields, understanding the differences between self-drilling and self-tapping screws is essential to performing construction tasks properly. Using the wrong type of fastener will result in weaker joints between materials, and a higher chance of structural failure.

Self-Drilling Screws

Self-Drilling Screws

Self-drilling screws are the most common type of screw. They have a tapering shaft with a continuous thread running from the point toward the screw head. The term "self-drilling" signifies that the screw is capable of drilling itself into a material; however, a pilot hole may be necessary to get the screw started. Self-drilling screws are not always designated as such; the term encompasses ordinary screws, machine screws and even specialty screws like drywall or wood screws.

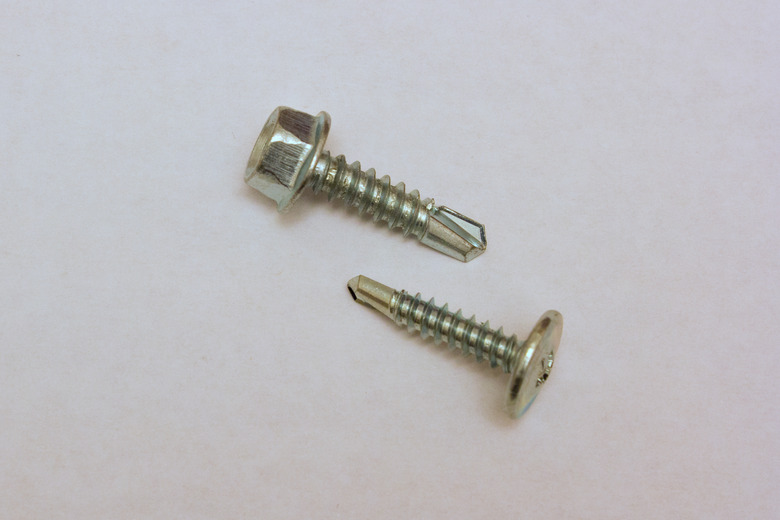

Self-Tapping Screws

Self-Tapping Screws

Self-tapping screws have a set of opposing vertical cutting blades at the tip. These twin blades drill a pilot hole, which avoids the need to use an actual drill bit. The term "self-tapping" describes the screw's ability to drill a pilot hole, which is also known as "tapping" a material. Self-tapping screws are ideal for drilling into metal and other hard materials, but are not useful for soft materials — such as wood — that require the screw to force a path into the material for increased holding strength. Self-tapping screws are more dependable for installing into stone or brick. Unlike ordinary self-drilling screws, the blades tap a hole of the correct diameter to allow thread insertion, without causing local stresses that can crack or shatter the material.

Self-Drilling Applications

Self-Drilling Applications

Self-drilling screws are common in woodworking projects, and applications involving thin or soft metals. If you use a self-tapping screw in wood, the tapped opening will be large enough that the screw threads cannot secure a load under more than minimal pressure. Self-drilling screws are also common in projects where pilot holes already exist. In these applications, the screw shaft must be larger than the pilot hole, so that the screw threads are able to gain a secure purchase.

Self-Tapping Applications

Self-Tapping Applications

Self-tapping screws are preferable in situations where the screw pattern is not pre-drilled, or there is no specific screw pattern. Self-tapping screws are useful for fastening metals, including steel, aluminum and brass. Although they work with most common material thicknesses, thick steel may require the use of multiple screws to tap the initial hole.