The Worst Metal Roofing Materials — And The Best Alternatives To Choose

You've decided on a metal roof. It's a hefty investment, but you've heard you'll get 40-70 years out of it and — being the optimistic sort — you're sure you'll get 70. The fun part will be choosing the metal to install, and you've got your eye on some copper that's gorgeous. Let's take a minute to be sure that's really how you want to go.

Not that copper is necessarily problematic. Most roofing problems ... or, at least, the most immediate and serious roofing problems ... are usually the result of installation issues rather than the homeowner's choice of materials. Certain choices do entail tradeoffs and, occasionally, problems. But, with the exception of bad engineering or bad manufacturing, most roofing materials have their place ... it just might not be on your home's roof.

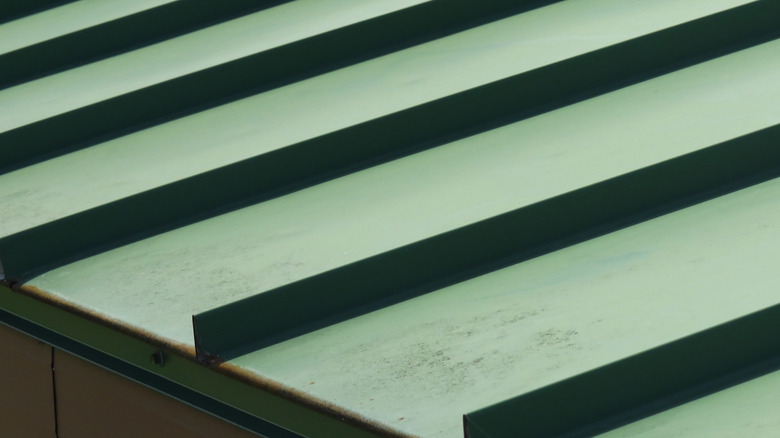

There are many ways to discuss types of metal roofing ... the makeup of the metal used, the thickness of that metal, finishes that might be applied to it, and the profile or shape of the material. We'll touch on the most likely problems you might have with each. The important thing to recognize is that there are trade-offs available everywhere, to dispel some myths about metal roofing, and to see that "ideal" is not an option. There is, however, a "best bet," and we'll get to that at the end. Also, we are focusing on vertical metal panels here, since that's still what most people mean by "metal roofing," and products like formed metal shingles are less likely to be troublesome.

It's better not to see the screws

Metal siding and roofing profiles — the shape that the metal is rolled into, as seen from the end of the panel — include a few general varieties like standing-seam, flat seam, corrugated and ribbed, but you might encounter them attached to any of a gazillion cute name brands like Master Rib or weird technical appellations like Double-Lok Trapezoidal. For the most part, when it comes to metal roofing, you'll be choosing between standing-seam panels and some type of corrugated panel, and the most useful way to think about these is that standing-seam metal has concealed fasteners (you can't see the screws), while corrugated metal has exposed screws with an integrated EPDM rubber washer.

The knocks on corrugated panels include that they have higher maintenance requirements; they are vulnerable to water intrusion; they aren't appropriate for roofs with less than a 3:12 pitch; and the overlap of the metal roofing panels means that you'll need more metal to cover the same surface area as with standing-seam panels. The increased maintenance is probably the biggest deal when comparing the two. Standing-seam panels are attached to clips, which are screwed to the roof decking without penetrating the metal. The exposed screws on a metal roof need to be inspected frequently and replaced periodically, as they represent many potential leak points. These clips also allow for more expansion and contraction of the metal, while the directly attached screw of corrugated panels tends to get stressed by natural movement. Corrugated panels are less expensive than standing-seam, though, and experience less "oil-canning" (visible wrinkling of the metal).

Low-quality materials have a certain lowness of quality to them

"Quality" is a broad concept that can include a lot of factors, from the grade of the steel used to create the panels to the thickness of the metal, the characteristics of coatings, and the uniformity of the manufacturing. The biggest concern here is probably the quality of the paint system applied to the metal coils from which the panels are formed. The best of these are layered polyvinylidene fluoride (PVDF) systems, like Kynar 500, which contain 70% PVDF. There are other resins besides PVDF that are also acceptable. Poor-quality paint systems will result in a roof that doesn't last as long or perform as well as a typical Kynar 500 or similar roof.

You could request and examine engineering reports for the metal panels you're considering, including wind uplift testing, water penetration testing, impact resistance testing, and fire rating reports. These should be available, and you should be concerned if they are not. However, it might be more efficient to ask a few key questions: Is the metal mill-certified? What is the paint system? What grade of steel was used? And, perhaps most important, what is the warranty on this metal? Typically, you'll get something like a 30-40-year warranty on the paint system, 15-25 years on the metal itself, and some kind of additional workmanship warranty from the contractor. If you're seeing anything substantially short of this, it might be cause for concern.

Galvanized steel roofing is a few shingles shy of a roof

Most steel roofing panels are referred to casually as "galvanized," but in the industry, it's important to distinguish between galvanized and other similarly treated metals. Steel is galvanized by an exterior coating of zinc that protects the steel from corrosion. This coating is effective but somewhat fragile, and steel coating with a system like Galvalume (sometimes branded Zincalume) can offer your roof panels a longer service life. Galvalume roofs are coated with an aluminum and zinc alloy and are generally warranted for 20 years. Galvanized is shinier — usually not a plus in a neighborhood — and eventually prone to rusting. Galvalume can rust, as well, but usually only at improperly cut edges. Properly sheared cuts will "self-heal" ... a process in which the protective coating acts as a sacrificial layer that oxidizes and stops any additional corrosion.

More than 90% of the steel roofing market is currently made up of Galvalume panels, but because galvanized steel is cheaper, you still encounter it for niche applications like housing animals and for accessory buildings. But for ordinary residential use, Galvalume is the hands-down winner here.

Copper, aluminum, zinc are bad, except when they're good

When one thinks of metal roofing, the first thing that pops to mind is probably the various metals themselves ... steel, copper, and perhaps more obscure choices like aluminum and zinc. Copper is a strange case. People tend to value it for one of its two traits: either its, umm, copper-colored finish when new, or its blue-green verdigris patina once it's aged for a number of years. It has great longevity, but is prone to damage because of the metal's softness. Copper is expensive, and the patina prized by some might be unwelcome in a neighborhood where the streaking and staining of adjacent materials isn't appreciated. Unless you're into the patina, copper-color paint systems are a good alternative.

Like most materials, aluminum has its place. That place is usually at the coast, where it excels at resisting the corrosive effects of saltwater exposure. On the other hand, it's somewhat expensive, although not as expensive as copper. It's also even softer than copper, so it's easily damaged, and it can weather somewhat unpredictably.

Zinc roofing is an extremely long-lived option that's, like aluminum, suitable for coastal areas and is, like copper, capable of forming a beautiful patina (though of a much more subdued hue than copper's). It's also self-healing by virtue of that patina, so that minor damage, like scratches, will not compromise the roof. On the other hand, it's expensive, prone to dents and chalking, and —worst of all — difficult to source in the U.S.

What to use instead

It's entirely possible that the right metal for your roof is any one of these materials, though probably not galvanized steel. A lot of this depends on your preferences, your tolerance for maintenance, your budget, and your ability to overlook minor damage. If the classic copper patina is your jam, you're only going to get it from copper. And if you're on a tight budget, corrugated metal might make more sense for your home than standing-seam. The important thing is that you go into the purchasing decision with your eyes open to all the trade-offs.

If you want to play it safe, the least troublesome and most high-performing option is clear: You'll want a standing-seam steel roof made with galvalume and using a Kymar 500 or comparable paint system. But we live in a world of individuals, and some of those will inevitably decide their preferences trump mundane issues like performance and longevity. And if you're such an individual, you roof you.