What Makes A Furnace "High Efficiency"?

Innovation in the design of furnace and boiler units over the last few decades has resulted in heating systems that extract significantly more energy from the combustion process in the form of heat and send less of it up the chimney as exhaust. Where old, large-bodied furnaces operate at less than 70 percent efficiency and relatively modern ones may achieve 80 to 83 percent efficiency, high-efficiency heating systems can offer efficiencies of 98 percent or more.

The ability of a furnace or boiler to capture all the energy it consumes is measured by its annual fuel utilization efficiency (AFUE). New furnaces and boilers are required by the Federal Trade Commission to display their AFUE rating so that consumers can make a comparison between models. Higher efficiency means that not only will you use less fuel for the same amount of heat, but your furnace will also emit less carbon dioxide into the atmosphere—as much as 1.5 tons less per year.

Furnace Efficiency Basics

Furnace Efficiency Basics

To understand how a high-efficiency furnace or boiler works, it's helpful to first review how a typical medium-efficiency unit works:

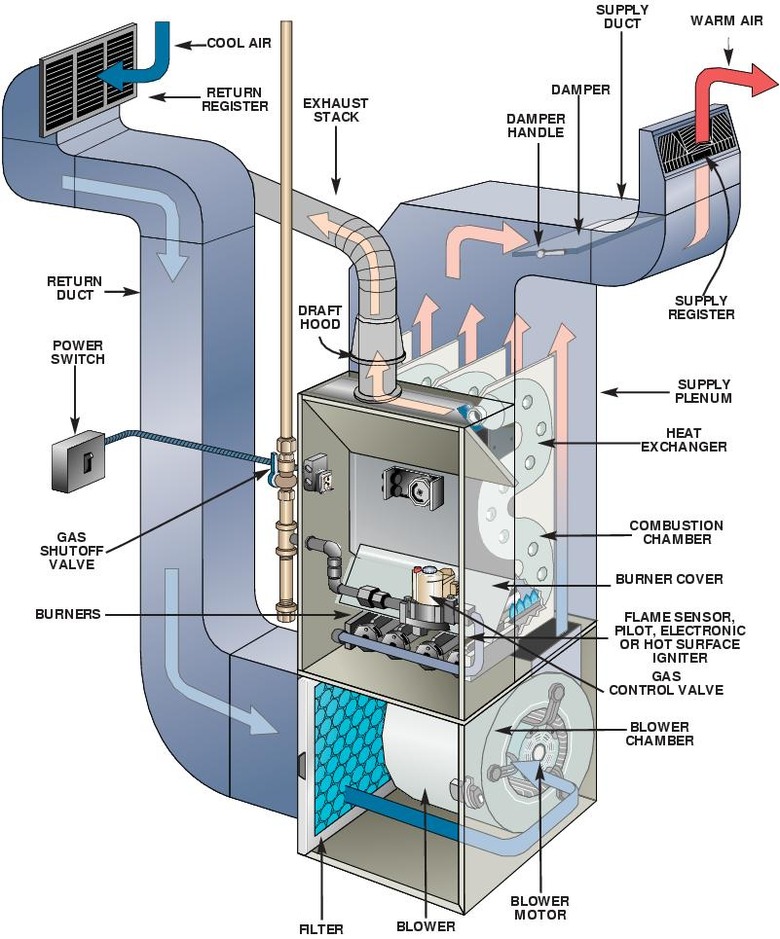

When your thermostat detects that the ambient temperature in your home has fallen below its set point, it sends a signal to the furnace. That signal prompts the gas valve to open and the burners to ignite in the combustion chamber. Older units have a constantly burning pilot light (also called a standing pilot) that ignites the gas that is delivered to the burners. Newer furnaces and boilers use an electronic ignition that is triggered at the same the gas valve opens to deliver gas to the burners.

Once the burners are engaged, the combustion chamber begins to heat up. Except for the flue that vents exhaust from the burner, the combustion chamber is a sealed box designed to confine that actual burning of fuel. Separate from the combustion chamber, but designed to be in contact with as much of the heat in the chamber as possible, is the heat exchanger. The air (or in the case of a boiler, water) in the heat exchanger snakes through the heated atmosphere of the combustion chamber, absorbing as much heat as possible.

Lower Efficiency Equals Money Up the Chimney

Lower Efficiency Equals Money Up the Chimney

In a low-efficiency gravity furnace, as soon as the air in the combustion chamber is warmer than the ambient air, it begins moving up and out the flue. Likewise, as soon as the air in the heat exchanger of a gravity furnace is warmer than the surrounding air, it begins making its way through the ductwork.

In medium-efficiency furnaces, a blower kicks in once the air in the combustion chamber reaches optimum temperature and the air in the heat exchanger is warmed. The blower not only propels the warm air into the ductwork to be distributed throughout the home, but it also draws in fresh air from the surrounding environment or from a dedicated fresh air intake.

With boiler systems, a pump circulates the heated water to the various radiators in the home. While the air or water inside the heat exchanger is being warmed by the surrounding atmosphere of the combustion chamber, the flame-heated air inside the chamber is continually moving up and out the flue. That plume spilling out of your chimney represents heat not captured—a sign of inefficiency.

What’s the Secret of High Efficiency?

What's the Secret of High Efficiency?

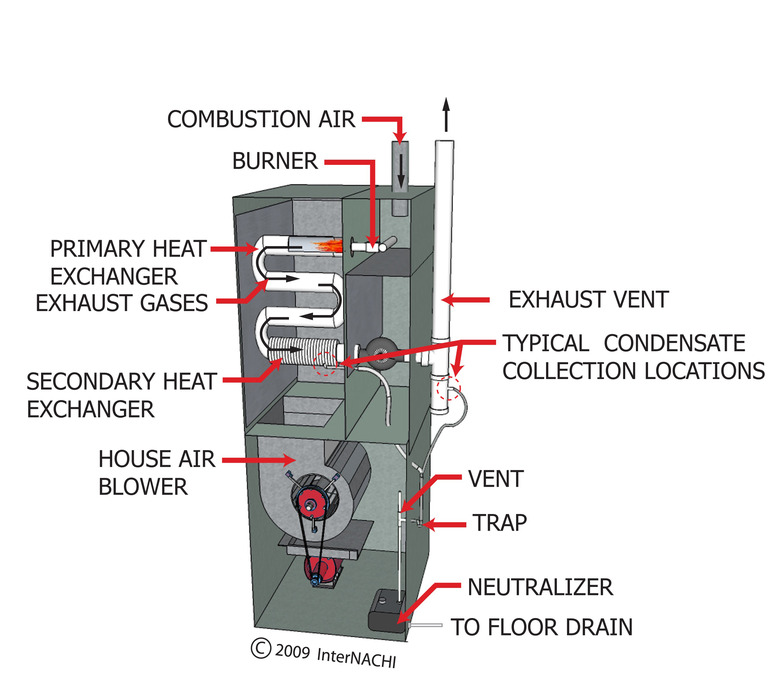

High-efficiency furnaces and boilers are engineered to capture and retain more of the energy produced by the burners. In the simplest sense, they do this by employing a secondary heat exchanger that follows the primary one and wrings most of the remaining heat out of the exhaust gases.

More specifically, the secondary heat exchanger is designed to condense the steam in the exhaust gas back into liquid water, which recovers most of the remaining heat energy. The exhaust that remains after the steam is condensed is cool enough that it can be expelled through a plastic CPVC or ABS venting, often horizontally through a nearby wall. In fact, the exhaust from a high-efficiency furnace or boiler is so cool, relatively, that it won't draw naturally through a venting system built for hotter exhaust. High-efficiency units compensate for that with a secondary draft-inducing fan at the base of the flue. The water produced by the condensation process is moderately acidic, and so the secondary heat exchanger must be constructed of a non-corrosive material, such as stainless steel or sometimes aluminum; that water is expelled through plastic tubing to a floor drain, often after being run through an alkaline neutralizing chamber.

One very simple way to identify a high-efficiency furnace is if you spot the CPVC or ABS vent pipe running through the sidewall of the house, or the plastic condensation tubing running to a floor drain. If a furnace does not have either of these features, it is not a high-efficiency unit.

High-efficiency furnaces and boilers are available in various levels of sophistication, some equipped with smart and sensitive controls that enable multiple levels of operation, depending on conditions. Unlike the traditional single-stage, all-or-nothing heating plants, many modern high-efficiency furnaces are capable of modulating their output with multi-level blowers that are quieter and less wasteful when the weather is moderately chilly and more forceful when cold weather hits. Some can also adjust the air and gas mixture delivered to the burners in order to fine-tune operations even more.

Is High Efficiency Always the Best Choice?

Is High Efficiency Always the Best Choice?

Without question, high-efficiency furnaces and boilers will cut fuel costs, making them cheaper to operate, and they'll emit less carbon dioxide, making them better for the environment. But whether or not that greater efficiency will pay for itself depends on a number of factors. Even after you take into account any cost differential between a conventional medium-efficiency unit and a high-efficiency one, you must also be prepared for the possible expense of adapting to cooler high-efficiency exhaust. Your chimney may need to be relined or modified to accommodate the new venting conditions. Horizontal venting through an outside wall might be uncomplicated—or it might not.

Your climate is a consideration, as well. If you live in a region with long, harsh winters, the savings you realize from a high-efficiency furnace or boiler will be substantially greater than if you live in a climate that is milder. Consult a furnace or boiler installation specialist you trust to determine what is involved in an upgrade to high efficiency. Every house will be different. You'll need to balance that information against the expectation of lower fuel cost, less environmental damage, and your own priorities.