4 Disadvantages Of Building With Insulated Concrete Forms

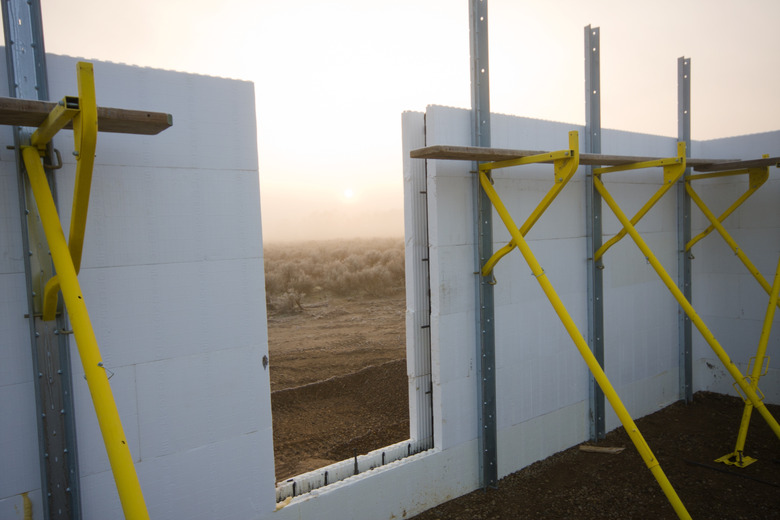

What if you could build a house with big Styrofoam Lego blocks? Since at least the 1960s — and probably before — that has in fact been an option. Insulated concrete form (ICF) construction isn't quite as simple as piecing together a Lego structure because the blocks are concrete forms, and there's the small matter of pouring the concrete after all the fun assembly work is completed. Once the concrete sets, though, you have solid, practically indestructible walls with a thick layer of Styrofoam insulation on both sides.

It isn't hard to think of the benefits of this construction method. For one thing, it saves on lumber, which is a dwindling resource. For another, the cost of raw materials, including forms, ties to hold them together, steel reinforcement bar, and concrete, is less than it is for a wood-framed house. There are many more benefits, but what about the drawbacks? It turns out there are a few of those too.

Here's what to know about the disadvantages of insulated concrete form construction.

1. The ICF Building Process Is Expensive

1. The ICF Building Process Is Expensive

With ICF construction, what you save in materials costs, you spend on labor and then some. Laborers must be highly specialized because one small mistake can ruin the whole project. If you're building in a region where qualified labor is in short supply, you may have to bring in workers from elsewhere, and although the assembly process involves very little heavy lifting, it's time-consuming. In the end, your final cost will probably be 40 percent higher than it would if you used another building technique.

Inexperienced builders can make small mistakes that can have big consequences. They may use a concrete mix with the wrong slump or aggregate, or they may fail to vibrate the concrete during the pour to make sure it settles to the bottom of the wall. That can leave holes that affect stability and allow moisture to pass.

2. ICF Construction Is Not Great in Cold Climates

2. ICF Construction Is Not Great in Cold Climates

In theory, you would expect such heavily insulated walls to reduce thermal transfer and keep the interior of the building warm in the winter. In practice, the opposite happens, and that's because of a necessary flaw in the system. The walls are designed to transfer heat of the building so that outside temperatures don't affect the curing process of the concrete. In a tropical climate, this heat transference can be a good thing, keeping the building cool during the day and comfortable at night, but in a cold climate, it means significantly higher heating costs.

3. Remodeling Is More Difficult With ICF

3. Remodeling Is More Difficult With ICF

Doors and windows are incorporated into the structure before the concrete is poured. Similarly, brackets for ledgers, beams, and other necessary components of interior framing have to be set in the walls before the pour so that they can be anchored by the concrete. All of this is extremely easy to do when setting up the forms, which are, after all, Styrofoam. It's very difficult to do and not always possible after the concrete has cured and hardened.

4. Moisture Can Seep Through ICF Walls

4. Moisture Can Seep Through ICF Walls

Plastic ties hold the two sides of the form together. These have a smooth finish that doesn't bond well with concrete and can allow moisture to wick inside the concrete. In addition, there are gaps between individual sheets that can allow moisture to pass through. Once leaks start to become noticeable on the inside of the structure, the sources are very difficult to locate, and the leaks are hard to control. To prevent this, a moisture-proof membrane should be installed on the outside wall.