How Does An Oil-Fired Boiler Work?

We may receive a commission on purchases made from links.

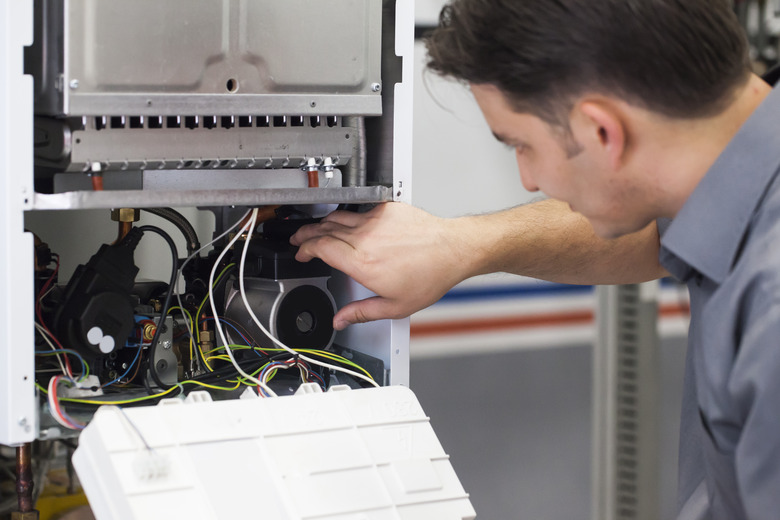

An oil-fired boiler uses oil rather than natural gas to provide your home with hot water and heating. Oil-fired boilers work much like gas boilers. Such systems boil oil to create hot water. The heated water then flows to your hot-water taps and through a water- or steam-based heating system.

Tip

An oil-fired boiler ignites oil in a combustion chamber, and then a heat exchanger heats up cold water. The resulting warm water is distributed throughout your home via hot-water taps and your hydronic heating system.

Oil-Fired Boiler Benefits

Oil-Fired

Boiler Benefits

When your home runs on an oil-fueled boiler, you don't need to connect to a natural gas line. Oil-fired boilers are a popular choice in geographic areas with limited access or no access to natural gas. They are also a good choice in terms of renewable fuel. This is especially the case if the oil is blended with biodiesel. Such biodiesel blends also produce less pollution than pure heating oil.

How Oil-Fired Heating Systems Work

How

Oil-Fired Heating Systems Work

Oil-fired boilers are an effective solution for residential water and home heating. An oil-fired boiler works in the same basic way as a gas boiler in that the boiler uses boiling oil to create hot water that is then sent to the hot-water taps in your home.

Oil-fired heating systems distribute heat throughout a home in one of three ways. The heat can travel through vents as warm air, as steam through radiators, or via hot water through baseboards.

When the thermostat senses that a room's temperature has fallen below the desired heat setting, it sends a signal to the oil-fired heating system to boil. The heated oil travels from the tank to a burner via a pump where it becomes a fine mist mixed with air. This fuel/air mixture enters the burner, where it ignites in the combustion chamber and begins heating the water.

Water-Based Heating System Types

Water-Based

Heating System Types

Two main types of water-based heating systems exist. These are hot-water heating systems and steam heating systems. With both systems, water is heated in a steel or cast-iron boiler and then distributed throughout the home.

With hot-water systems, the heated water circulates throughout your home via radiators or baseboards. Steam systems feature water turning to steam and rising through pipes to radiators.

Oil-Fired vs. Gas-Fired Boilers

Oil-Fired

vs. Gas-Fired Boilers

Both oil-fired and gas-fired boilers have their benefits and drawbacks. Which type you choose for your home will depend on several considerations.

Oil-fired furnaces tend to be less efficient than gas-fired heating systems in terms of annual fuel utilization efficiency. This rating is a measurement of the efficiency of a machine's combustion. Fuel prices for oil-fired systems are also higher than those for gas-fired systems, and you must get the oil delivered and store it on your property. The maintenance for oil-fired furnaces is also more extensive and more frequently required than the maintenance for gas-fired furnaces.

On the other hand, gas-fired furnaces tend to be 10 to 25 percent higher in price than equivalent oil-fired furnace models. Such furnaces also provide less heat per BTU than oil-fired furnaces. In addition, your home must be located where a gas supply is available.